联系我们

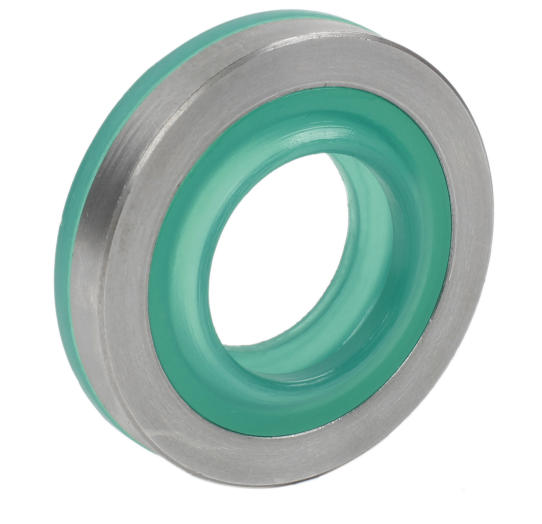

U型密封元件

关键词:

所属分类:

Performance and Purpose:

It makes use of the advantage of Polyurethane,such as high strength, hardness,good elasticity and high-wearing feature. The type U of sealing component is used in the hydraulic testing of oil well casing tube,steel pipe and a variety of welded steel pipes of the Petroleum and Natural Gas Industry.

利用聚氨酯材料强度高、硬度大、弹性好、高耐磨等综合性能突出的特点,所制造的密封圈用于石油天然气工业——油气井套管、油管及各种焊接钢管的耐压试验。

Advantage:

The outer wall or inner wall of steel pipe can be sealed according to the situation.

可根据情况密封钢管外壁或者钢管内壁

The sealing structure is simple than the other sealing rings.

密封试压结构简单

Working conditions:

According with several standards about hydraulic testing requirements:such as API 5CT/ISO11960:2011, GB/T9711.1-2011, GB/T9711.2-2011,etc. for Petroleum and natural gas industries—Steel pipes for casing or tubing; GB8163 - 2008 for seamless steel tubes; GB/T3092-2008 for welded steel pipes.

符合API 5CT/ISO11960:2011、GB/T9711.1-2011、GB/T9711.2-2011等石油天然气工业——油气井套管或油管用钢管;GB8163-2008无缝钢管;GB/T3092-2008焊接钢管等标准水压试验条件。

Working pressure: ≤ 80 MPa

Working temperature: -20℃~+80℃

Working medium: water, emulsion, hydraulic oil

Material: Polyurethane

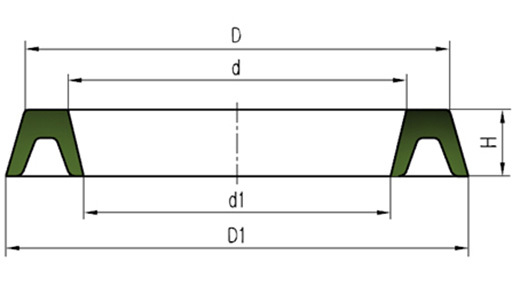

| 序号 No. | 规格型号 Type | 公制尺寸 Metric size | 密封圈尺寸 Seal dimensions | 订货号 Order No. | ||||

| d | d1 | D | D1 | H | ||||

| 1 | U15.88 | 15.88 | 21 | 15 | 84 | 87 | 42 | U632 |

| 2 | U19 | 19 | 24 | 18 | 84 | 87 | 42 | U629 |

| 3 | U25.4 | 25.4 | 30.5 | 24.2 | 84 | 87 | 42 | U631 |

| 4 | U33.4 | 33.4 | 38.5 | 32.4 | 84 | 87 | 42 | U634 |

| 5 | U38.1 | 38.1 | 43 | 37 | 93 | 96 | 42 | U635 |

| 6 | U42 | 42 | 47 | 41 | 93 | 96 | 42 | U636 |

| 7 | U44.5 | 44.5 | 49.5 | 43.5 | 100 | 103 | 42 | U637 |

| 8 | U48.3 | 48.3 | 53 | 47 | 100 | 103 | 42 | U638 |

| 9 | U50.8 | 50.8 | 55.5 | 49.5 | 100 | 103 | 42 | U639 |

| 10 | U60.3 | 60.3 | 65.6 | 59.5 | 110.5 | 114.5 | 42 | U604 |

| 11 | U63.5 | 63.5 | 69 | 62.2 | 110.5 | 114.5 | 42 | U640 |

| 12 | U73.03 | 73.03 | 78.3 | 72 | 123 | 127 | 42 | U605 |

| 13 | U75.5 | 75.5 | 81 | 74.1 | 123 | 127 | 42 | U641.1 |

| 14 | U76.2 | 76.2 | 81 | 75 | 123 | 127 | 42 | U641 |

| 15 | U88.9 | 88.9 | 93.5 | 87.5 | 139 | 142 | 42 | U607 |

| 16 | U93.17 | 93.17 | 97.4 | 91.5 | 144 | 147 | 42 | U608 |

| 17 | U101.6 | 101.6 | 105.4 | 100 | 152 | 155 | 42 | U609 |

| 18 | U114.3 | 114.3 | 119 | 113 | 165 | 168 | 42 | U611 |

| 19 | U139.7 | 139.7 | 144.6 | 138 | 193 | 195 | 42 | U615 |

| 20 | U153.67 | 153.67 | 157.5 | 152 | 204 | 207 | 42 | U616 |

| 21 | U177.8 | 177.8 | 181.5 | 175.5 | 226 | 230 | 42 | U618 |

| 22 | U194.46 | 194.46 | 199.3 | 192 | 243 | 247 | 42 | U620 |

专业从事钢管静水压试验用超高压密封元件研制、生产、销售的科技型生产企业。公司致力于钢管水压试验机用密封元件的研究和生产,拥有较强的专业研发团队及优秀的售后服务人员。先后与国内十余家著名水压试验机设计单位建立合作关系,为其配套设计,生产各种新型密封产品。标准静水压试验要求,性能稳定,使用寿命长,畅销国内及东南亚市场,深受国内外用户的一致好评。

在线咨询

北京建科汇峰科技有限公司