联系我们

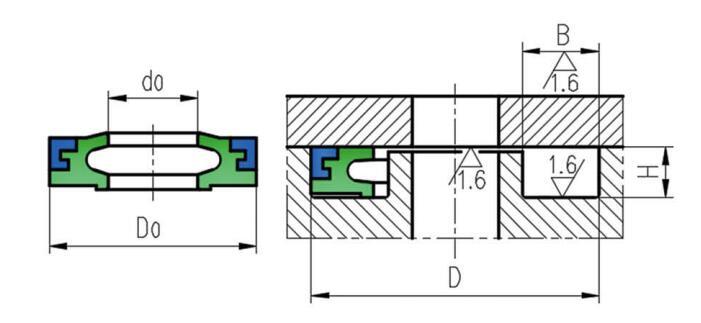

PYG型密封元件

关键词:

所属分类:

Performance and Purpose

It is the faced sealing with section of “Y”. It is designed specifically for steel pipe hydrostatic testing machine to seal the plane on water filling and air exhaust test head. When installing, Make the two planes a close contact, and pay attention to the installation direction of the sealing ring.

它是一个断面呈Y形的平面密封圈,专为钢管水压试验机充水试压头和排气试压头之平面密封而设计。安装时要求两平面接触严密,并注意密封圈的安装方向。

Advantage

It is a sealing element consisting of a PY type face sealing and a steel skeleton.

它是由一个PY型平面密封圈和一个骨架组成的密封元件

Close contact between the two planes is required. During installation, and attention should be paid to the installation direction of the sealing ring.

安装时要求两平面接触严密,并注意密封圈的安装方向。

The support framework enhances the overall strength of the seal ring and the sealing capacity of sealing ring can be increased by working pressure.

支撑骨架增强密封圈整体强度

The sealing material has the advantage of high strength, high hardness and good elasticity

密封材料强度大、硬度大、弹性好

Working conditions:

According with several standards about hydraulic testing requirements:such as API 5CT/ISO11960:2011, GB/T9711.1-2011, GB/T9711.2-2011,etc. for Petroleum and natural gas industries—Steel pipes for casing or tubing; GB8163 - 2008 for seamless steel tubes; GB/T3092-2008 for welded steel pipes.

符合API 5CT/ISO11960:2011、GB/T9711.1-2011、GB/T9711.2-2011等石油天然气工业——油气井套管或油管用钢管;GB8163-2008无缝钢管;GB/T3092-2008焊接钢管等标准水压试验条件。

Working pressure: ≤ 120 MPa

Working temperature: -20℃~+80℃;

Working medium: water, emulsion, hydraulic oil;

Material: Polyurethane+ Steel Skeleton

| 序号 No. |

规格型号 Type |

密封圈尺寸Seals Dimension | 沟槽尺寸 Groove dimension |

订货号 Order No. |

|||

| d0 | D0 | DH11 | B+0.25 | H+0.1 | |||

| 1 | PYG25×10 | 8 | 25 | 25 | 10 | 10 | PY101 |

| 2 | PYG30×10 | 12 | 30 | 30 | 10.5 | 10 | PY102 |

| 3 | PYG36×10 | 16 | 36 | 36 | 12 | 10 | PY106 |

| 4 | PYG48×10 | 24 | 48 | 48 | 14 | 10 | PY123 |

| 5 | PYG50.2×10 | 23.8 | 50.2 | 50.2 | 15 | 10 | PY109 |

| 6 | PYG55×7.5 | 35 | 55 | 55 | 11.8 | 7.5 | PY146 |

| 7 | PYG60×15.2 | 30 | 60 | 60 | 17.5 | 15.2 | PY100B |

| 8 | PYG90×10 | 63.6 | 90 | 90 | 16 | 10 | PY125 |

| 9 | PYG105×7 | 85 | 105 | 105 | 11.8 | 7.2 | PY147 |

| 10 | PYG142×10 | 115.6 | 142 | 142 | 16 | 10 | PY124 |

| 11 | PYG155×7 | 135 | 155 | 155 | 11.8 | 7.2 | PY144 |

| 12 | PYG165×10 | 143 | 165 | 165 | 13 | 10 | PY148 |

| 13 | PYG180×10 | 152.4 | 180 | 180 | 16 | 10 | PY127 |

| 14 | PYG190×10 | 162.4 | 190 | 190 | 16 | 10 | PY128 |

| 15 | PYG200×10 | 172.5 | 200 | 200 | 16 | 10 | PY130 |

| 16 | PYG230×7.5 | 210 | 230 | 230 | 11.8 | 7.5 | PYG043 |

| 17 | PYG240×10 | 212.4 | 240 | 240 | 16 | 10 | PY107 |

| 18 | PYG260×10 | 232 | 260 | 260 | 16 | 10 | PY126 |

| 19 | PYG300×7 | 280 | 300 | 300 | 11.8 | 7.2 | PY142 |

| 20 | PYG350×10 | 322.4 | 350 | 350 | 16 | 10 | PY111 |

| 21 | PYG370×10 | 342 | 370 | 370 | 16 | 10 | PY108 |

| 22 | PYG390×10 | 362.4 | 390 | 390 | 16 | 10 | PY112 |

| 23 | PYG410×10 | 382.4 | 410 | 410 | 16 | 10 | PY113 |

| 24 | PYG440×10 | 412.4 | 440 | 440 | 16 | 10 | PY114 |

| 25 | PYG450×10 | 422.4 | 450 | 450 | 16 | 10 | PY110 |

| 26 | PYG460×10 | 432.4 | 460 | 460 | 16 | 10 | PY116 |

| 27 | PYG480×10 | 452.4 | 480 | 480 | 16 | 10 | PY117 |

| 28 | PYG540×10 | 512.4 | 540 | 540 | 16 | 10 | PY118 |

| 29 | PYG600×10 | 572.4 | 600 | 600 | 16 | 10 | PY119 |

| 30 | PYG665×10 | 637.4 | 665 | 665 | 16 | 10 | PY115 |

| 31 | PYG720×10 | 692.4 | 720 | 720 | 16 | 10 | PY120 |

| 32 | PYG770×10 | 742.4 | 770 | 770 | 16 | 10 | PY121 |

| 33 | PYG800×10 | 772.4 | 800 | 800 | 16 | 10 | PY122 |

专业从事钢管静水压试验用超高压密封元件研制、生产、销售的科技型生产企业。公司致力于钢管水压试验机用密封元件的研究和生产,拥有较强的专业研发团队及优秀的售后服务人员。先后与国内十余家著名水压试验机设计单位建立合作关系,为其配套设计,生产各种新型密封产品。标准静水压试验要求,性能稳定,使用寿命长,畅销国内及东南亚市场,深受国内外用户的一致好评。

上一页

下一页

上一页

PY型密封元件

下一页

在线咨询

北京建科汇峰科技有限公司